Raw Food Ingredients

How Is Raw Cacao Pricessed Into Cocoa

Picture a voyage, in which the modest raw cacao bean undergoes a metamorphosis into the smooth, decadent treat we recognize as cocoa. This metamorphosis, akin to a mystical alchemy, includes a sequence of exacting and complex processes that reveal the genuine essence of this extraordinary ingredient.

As a food scientist, I have delved into the depths of this journey, unlocking the secrets behind each step and uncovering the science behind the flavors.

From the origins of raw cacao to the final packaging and distribution, I will guide you through the meticulous steps involved in processing this precious bean. We will explore the art of roasting the cacao beans, the grinding and winnowing process that separates the precious nibs from the husks, and the pressing of the cacao paste to extract its luscious oils.

We will dive into the conching process, where the chocolate is refined and transformed into its smooth, silky texture. And finally, we will delve into the tempering, molding, and cooling that bring the cocoa to its final form.

Join me on this fascinating journey, as we unlock the secrets of how raw cacao is processed into cocoa.

Key Takeaways

- Fermentation and drying enhance flavor.

- Roasting at precise temperatures develops cocoa aroma.

- Processing separates cocoa solids from cocoa butter.

- Refining and conching reduce bitterness and achieve smoothness.

The Origins of Raw Cacao

Take a moment to imagine yourself standing in the lush rainforests of South America. The rich soil and tropical climate give birth to the exquisite raw cacao beans that will soon be transformed into decadent cocoa.

Raw cacao has been revered for its health benefits and cultural significance in ancient civilizations.

To convert raw cacao into cocoa, a series of precise and technical processes are employed.

First, the raw cacao beans are carefully harvested and fermented to develop their distinct flavor. Then, they are dried and cleaned to remove any impurities.

Next, the beans are roasted at specific temperatures to bring out their aromas and deepen their flavors. This crucial step sets the foundation for the subsequent processes that will further transform the beans into cocoa.

Roasting the Cacao Beans

When roasting cacao beans, the first step is to enhance their flavor and aroma. This is achieved by subjecting the beans to different roasting techniques, such as low and slow roasting or high heat roasting.

Monitoring the temperature and time during the roasting process is crucial to ensure optimal flavor development and prevent over-roasting or under-roasting. By carefully controlling these variables, food scientists and technologists can achieve the desired balance of flavors and aromas in the final cocoa product.

Enhancing Flavor and Aroma

To truly elevate the taste and scent of raw cacao, artisans skillfully employ various techniques to unlock its full potential and create an unforgettable cocoa experience. These techniques include improving the fermentation process and exploring different flavor profiles.

-

Fermentation Enhancement: Artisans carefully control the temperature and duration of the fermentation process to optimize flavor development. This critical step allows the breakdown of complex compounds, releasing desirable flavor compounds and reducing bitterness.

-

Flavor Profiling: By varying fermentation conditions such as time, temperature, and microbial strains, artisans can achieve different flavor profiles in the cocoa beans. This allows for the creation of unique and distinct cocoa flavors, ranging from fruity and floral to nutty and earthy.

-

Microbial Inoculation: Some artisans introduce specific microbial strains during fermentation to enhance flavor complexity and depth. These strains can produce enzymes that further break down undesirable compounds and create desirable flavor precursors.

-

Aroma Preservation: To preserve the delicate aromas of the cocoa, artisans ensure proper drying and storage conditions. This prevents the loss of volatile aroma compounds, ensuring a rich and enticing aroma in the final cocoa product.

Moving on to different roasting techniques, let’s explore how this crucial step further enhances the flavor and aroma of cocoa.

Different Roasting Techniques

Let’s now delve into the world of different roasting techniques and discover how they enhance the flavor and aroma of our beloved cocoa.

The roasting process plays a crucial role in flavor development as it involves the Maillard reaction, which creates desirable flavor compounds.

Different roasting techniques, such as light, medium, and dark roasts, result in varying flavor profiles.

Light roasts preserve the delicate fruity and floral notes of the cacao, while medium roasts bring out more nutty and caramel flavors.

Dark roasts, on the other hand, produce a robust and bitter taste.

The duration and temperature of the roasting process also influence the flavor intensity.

Longer roasting times and higher temperatures can create deeper, more pronounced flavors.

However, excessive heat or extended roasting can lead to undesirable burnt or ashy flavors.

Monitoring temperature and time during the roasting process is crucial to achieve the desired flavor profile.

Monitoring Temperature and Time

Careful monitoring of temperature and time during the roasting process is crucial in order to achieve the desired flavor profile, ensuring that each batch of cocoa beans undergoes the transformation into a delectable treat.

The temperature range for roasting raw cacao beans typically falls between 120°C and 140°C, depending on the desired flavor and aroma. This temperature range allows for the Maillard reaction to occur, which is responsible for the development of the characteristic chocolate flavor.

Additionally, the duration of the roasting process can vary from 10 to 30 minutes, depending on the desired intensity of flavor. Consistency in temperature and time is key to ensure that each batch of cocoa beans is roasted to perfection. By maintaining consistency, the flavor and quality of the resulting cocoa can be optimized.

Moving on to the next step of the process, grinding and winnowing…

Grinding and Winnowing

First, you crack open the raw cacao beans to reveal the rich cocoa nibs inside. To transform these nibs into cocoa, the next step is grinding and winnowing. Grinding techniques involve using specialized equipment like stone grinders or ball mills to break down the cocoa nibs into a fine paste called cocoa liquor. This process requires careful control of temperature and time to prevent overheating and preserve the delicate flavors. Once the cocoa liquor is obtained, winnowing is performed to separate the husks from the cocoa solids. This is typically done using machines that apply air or vacuum to remove the lighter husks, leaving behind the valuable cocoa mass. With the husks removed, the resulting cocoa solids can then be further processed into cocoa powder or chocolate. Next, we will explore the crucial step of pressing the cacao paste to obtain cocoa butter and cocoa cake.

Pressing the Cacao Paste

To fully appreciate the richness and decadence of chocolate, you need to uncover the hidden treasures locked within the cacao paste. Pressing techniques play a crucial role in this process.

The cacao paste, obtained from grinding and winnowing, is subjected to pressing to separate the cocoa solids from the cocoa butter. Pressing involves applying pressure to the paste, which helps to extract the cocoa butter and leave behind a solid cake.

This cake is then further processed to produce cocoa powder. The benefits of pressing include the removal of excess cocoa butter, which can affect the texture and flavor of the final cocoa product. Additionally, pressing helps to enhance the homogeneity and consistency of the cocoa powder.

As we move into the subsequent section about ‘conching the chocolate,’ the pressed cocoa cake awaits its next transformation.

Conching the Chocolate

Once you’ve pressed the cacao paste, it’s time to embark on the next step of the chocolate-making journey – conching. Imagine this process as a gentle dance between the chocolate particles and the conching machine, where they swirl and mingle, transforming into a smooth and velvety treat that will melt in your mouth.

During the chocolate conching process, several key transformations occur. Here are five important aspects to consider:

- Frictional heat generated in the conching machine helps melt and distribute cocoa butter evenly.

- The continuous agitation breaks down large particles, resulting in a finer texture.

- Acidic compounds naturally present in cocoa are neutralized, reducing bitterness and enhancing flavor.

- The conching time and temperature are carefully controlled to optimize the texture and flavor development.

- Volatile compounds are evaporated, improving the aroma and removing any undesirable flavors.

By understanding and optimizing the conching process, we can create chocolate with the perfect balance of smoothness, flavor, and aroma.

Now, let’s transition to the subsequent section about tempering the chocolate.

Tempering the Chocolate

After conching the chocolate, the next crucial step in the process of converting raw cacao into cocoa is tempering. Tempering is a technique that involves carefully controlling the temperature of the chocolate to ensure it has the desired texture, appearance, and shelf life.

The importance of temperature control cannot be overstated, as it allows for the formation of stable cocoa butter crystals within the chocolate. This is achieved by gradually cooling and reheating the chocolate to specific temperatures, which encourages the proper crystallization and alignment of the cocoa butter.

Tempering techniques can vary, but common methods include seeding and tabling. These techniques require precise monitoring of temperatures, typically between 80-90°F (27-32°C), to achieve the desired results.

The successful tempering of chocolate is essential for creating a smooth, glossy finish and preventing the formation of unwanted fat bloom.

Moving on to the subsequent section about molding and cooling…

Molding and Cooling

When molding and cooling chocolate, the first step is pouring the melted chocolate into molds. This is done carefully to ensure that the chocolate fills each mold evenly and without any air bubbles.

Once poured, the chocolate is left to set at room temperature or placed in a cooling chamber to accelerate the process.

Cooling and solidifying the chocolate is crucial as it allows the cocoa butter to harden and gives the final product its desired texture and appearance.

This process requires precise temperature control to prevent any crystallization issues and achieve the desired glossy finish.

Pouring the Chocolate into Molds

To achieve the desired shape, carefully pour the luscious chocolate into the molds, using precision and expertise in the shaping process. The temperature of the chocolate must be closely monitored to ensure it is at the optimal level for pouring, typically around 86°F to 90°F (30°C to 32°C).

The chocolate is poured into the molds using a ladle or a specialized pouring device, ensuring that each mold is filled evenly. Once filled, the molds are gently tapped on a surface to remove any air bubbles and to ensure that the chocolate settles evenly.

After pouring, the molds are transferred to a cooling chamber, where the chocolate is allowed to cool and solidify into delectable cocoa treats. This cooling process typically takes around 20 to 30 minutes.

Once the chocolate has set, it can be easily removed from the molds, ready to be packaged and enjoyed.

Allowing the Chocolate to Set

Once the chocolate has hardened, it’s time to savor the anticipation of biting into a perfectly formed, mouthwatering treat. Allowing the chocolate to set is a crucial step in the process of transforming raw cacao into cocoa.

Food scientists and technologists experiment with different textures and techniques to achieve the desired consistency and flavor. This process involves carefully controlling the temperature and humidity levels to ensure proper crystallization of the cocoa butter. By manipulating these factors, they can influence the final texture of the chocolate, whether it be smooth and creamy or firm and snappy.

Additionally, the time duration for allowing the chocolate to set can vary depending on the specific recipe and desired outcome. It is essential to strike the right balance between allowing enough time for the chocolate to solidify and preventing over-crystallization.

With the chocolate now set, it’s time to move on to the next step: cooling and solidifying the chocolate further.

Cooling and Solidifying the Chocolate

After allowing the chocolate to set, the next step in the process of converting raw cacao into cocoa is cooling and solidifying the chocolate. This step is crucial in achieving the desired texture and consistency of the final cocoa product.

Cooling techniques are employed to rapidly lower the temperature of the chocolate, causing it to solidify. This can be done using specialized cooling tunnels or refrigeration units, which maintain precise temperatures and airflow to ensure even cooling.

As the chocolate cools, the cocoa butter within it crystallizes, resulting in a smooth and glossy appearance. The rate at which the chocolate solidifies can affect its final texture, so it is important to carefully control the cooling process.

Once the chocolate has solidified, it is ready for the next stage of packaging and distribution.

Packaging and Distribution

Packaged in vibrant, eye-catching boxes and shipped to chocolate lovers worldwide, the rich and velvety cocoa undergoes a meticulous distribution process.

Utilizing packaging innovations and efficient logistics, the goal is to ensure that every package of cocoa reaches its destination in perfect condition.

Advanced techniques such as vacuum sealing and temperature-controlled storage are employed to preserve the quality and flavor of the cocoa.

Global distribution networks are established to meet the demand from various regions, with careful consideration given to environmental factors, transportation routes, and delivery timelines.

Additionally, collaboration with retailers and online platforms helps to make the cocoa readily available to consumers.

By prioritizing quality control and efficient distribution, the industry strives to provide chocolate enthusiasts with a satisfying and enjoyable experience.

Enjoying the Finished Product

Savoring the final product, chocolate lovers around the world relish in the indulgent velvety texture and rich flavors that dance on their taste buds.

The journey from raw cacao to cocoa involves several crucial steps that contribute to the delightful experience.

Firstly, the raw cacao beans are fermented and dried to enhance their flavor profile. Then, they undergo roasting at precise temperatures to develop the characteristic cocoa aroma.

Next, the roasted beans are ground into a paste, known as cocoa liquor, which is further processed to separate the cocoa solids from the cocoa butter. This stage involves pressing the cocoa liquor to extract the cocoa butter, leaving behind the cocoa powder.

Lastly, the cocoa powder is refined and conched to achieve the desired smoothness and reduce any remaining bitterness. The result is a fine cocoa powder that can be used in various culinary creations, allowing chocolate enthusiasts to fully enjoy the taste and reap the health benefits of cocoa.

Frequently Asked Questions

What are the health benefits of consuming raw cacao?

Consuming raw cacao has numerous health benefits. It is rich in antioxidants, fiber, and minerals such as magnesium and iron. Its high nutrition content can support cardiovascular health, improve mood, and boost cognitive function.

Can raw cacao be used in baking recipes?

Raw cacao can be used in baking, but there are pros and cons. Pros include rich flavor and potential health benefits, while cons include bitterness and potential texture issues. Alternatives to raw cacao in baking recipes include cocoa powder or chocolate chips.

How does the flavor of raw cacao differ from processed cocoa?

The flavor profile of raw cacao differs from processed cocoa due to the absence of roasting, which preserves its natural fruity and bitter notes. Additionally, raw cacao retains higher nutritional value with more antioxidants, vitamins, and minerals.

What are some common uses for cocoa powder?

Cocoa powder is commonly used in baking and drinks. It adds a rich, chocolatey flavor and a dark color to recipes. From chocolate cakes to hot chocolate, cocoa powder enhances the taste and appearance of many delicious treats.

How does the quality of raw cacao affect the final chocolate product?

The quality of raw cacao greatly impacts the final chocolate product. Factors such as raw cacao sourcing and the fermentation process can affect the flavor, aroma, texture, and overall quality of the cocoa.

How Is Raw Cacao Processed and How Can I Use It to Make Cocoa at Home?

Raw cacao in Brevard County is typically processed by fermenting, drying, roasting, and grinding the cacao beans. To make cocoa at home, simply grind the raw cacao beans into a powder and mix with hot water or milk. Add sweetener to taste and enjoy a homemade cup of rich, chocolatey cocoa.

Conclusion

In conclusion, the process of converting raw cacao into cocoa is a precise and technical endeavor. As a food scientist, I have examined the origins of raw cacao and the steps involved in roasting, grinding, pressing, conching, tempering, molding, and packaging.

Each step requires specific temperatures, time durations, and chemical reactions. It is crucial to adhere to industry standards and scientific research to ensure the highest quality cocoa.

Through analytical and critical thinking, we can continue to improve and innovate in the processing of raw cacao, always striving for excellence.

Remember, as the adage goes, "With precision and expertise, cocoa is transformed, bringing joy to those who indulge."

"With every meticulous step and relentless pursuit of perfection, we unlock the true essence of cocoa, crafting an unparalleled delight that captivates the senses and brings blissful moments to all who savor its decadence."

Rachael, the Editor in Chief of RachaelsRawFood.com, is an inspiring and passionate individual who has dedicated her life to promoting the benefits of a raw food lifestyle. Known for her vibrant and energetic personality, Rachael has built a strong online presence that has transformed her personal journey into a thriving community of raw food enthusiasts.

Raw Food Ingredients

How Much Caffeine in Cocoa?

Not all cocoa products are created equal when it comes to caffeine content – discover which one might surprise you!

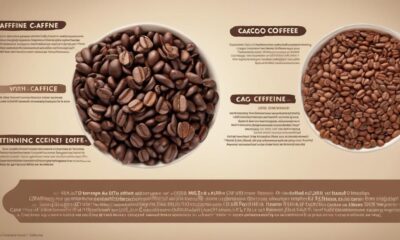

When evaluating the caffeine levels in cocoa, it’s important to recognize that dark chocolate contains around 43 mg of caffeine per 100 grams due to its high cocoa solid content. Dark chocolate has a higher caffeine content compared to milk or white chocolate. This means that consuming dark chocolate in moderation can assist in managing your caffeine intake. On the other hand, milk chocolate has around 20 mg of caffeine per 100 grams while white chocolate is caffeine-free. Cocoa powder, commonly used in baking and beverages, contains a substantial 230 mg of caffeine per 100 grams. Being aware of these distinctions in chocolates can help you make informed decisions about your caffeine consumption.

Key Takeaways

- Caffeine content in cocoa varies based on cocoa solid concentrations.

- Unsweetened cocoa powder can contain around 230 mg of caffeine per 100 grams.

- Roasting cocoa solids influences the final caffeine content in cocoa products.

- Dark chocolate, with high cocoa solid content, has more caffeine than milk chocolate.

- Moderate consumption of cocoa products helps manage caffeine intake.

Caffeine Content in Dark Chocolate

Dark chocolate boasts a caffeine content of approximately 43 mg per 100 grams, mainly deriving from its higher cocoa solid composition. When we indulge in this decadent treat, we aren't only savoring its rich cocoa flavor but also a subtle caffeine kick. Compared to milk or white chocolate, dark chocolate contains a higher amount of caffeine.

Please bear in mind that moderate consumption of dark chocolate can assist individuals in managing their caffeine intake effectively. The caffeine levels in dark chocolate are about one-fourth of what you'd find in a standard cup of coffee. So, if you're looking for a milder caffeine boost, a piece of dark chocolate might just do the trick without the jitters that sometimes accompany a strong cup of coffee.

Enjoy your dark chocolate in moderation, savoring both its taste and the gentle pick-me-up it provides.

Caffeine Levels in Milk Chocolate

Milk chocolate, known for its creamy texture and sweet flavor, contains a modest caffeine content of approximately 5.6 mg per ounce, as indicated by USDA data. Unlike dark chocolate, milk chocolate has a lighter color due to lower cocoa content, resulting in reduced caffeine levels.

The delightful creamy taste in milk chocolate comes from a harmonious blend of cocoa and milk powder. While dark chocolate boasts higher caffeine content, milk chocolate remains a popular choice for those seeking a sweet treat with minimal caffeine intake.

Caffeine Presence in White Chocolate

With its unique composition excluding cocoa solids, white chocolate stands out as a caffeine-free alternative to its darker counterparts. White chocolate is crafted from a blend of cocoa butter, milk powder, sugar, and vanilla, making it a delectable treat without the stimulating effects of caffeine. For individuals sensitive to caffeine, white chocolate offers a creamy texture and indulgent flavor without the worry of unwanted side effects. This makes it a popular choice for desserts among those looking to steer clear of caffeine in their sweet treats.

Compared to dark chocolate, which contains cocoa solids and hence caffeine, white chocolate provides a caffeine-free option for those seeking a more mellow indulgence. So, if you're in the mood for a luscious and smooth chocolate experience without the buzz of caffeine, white chocolate is the perfect choice for your next dessert delight.

Impact of Cocoa Solids on Caffeine

In determining the caffeine levels in cocoa products, the percentage of cocoa solids plays a significant role. Here are some key points about the impact of cocoa solids on caffeine content:

- Caffeine Derivation: The caffeine content in cocoa primarily comes from cocoa solids, making it an important factor in determining the overall caffeine levels in cocoa-based products.

- Dark Chocolate: Dark chocolate, known for its higher cocoa solid content, tends to contain more caffeine compared to milk or white chocolate varieties due to this higher concentration.

- Unsweetened Cocoa Powder: A 100g serving of unsweetened cocoa powder can contain around 230mg of caffeine, reflecting the impact of the high cocoa solid content in this form.

- Health Benefits: The roasting process of cocoa solids not only affects the flavor profile but also influences the caffeine content, contributing to the potential health benefits associated with consuming cocoa products like hot cocoa.

Comparing Caffeine in Different Chocolates

Comparing the caffeine content in different chocolates reveals varying levels based on their cocoa solid concentrations. Dark chocolate contains about 43 mg of caffeine per 100 grams, making it a stronger caffeinated option compared to milk chocolate, which only has around 20 mg per 100 grams.

Surprisingly, white chocolate, derived from cocoa butter, doesn't contain any caffeine at all. For those seeking a more potent caffeine kick, cocoa powder is the way to go, boasting a high concentration of 230 mg per 100 grams.

The amount of caffeine in chocolate products is closely linked to the cocoa solid content, with dark chocolate containing the highest levels. So, the next time you're craving a chocolate treat but also need a little energy boost, opt for dark chocolate to get the most caffeine per bite.

Frequently Asked Questions

Is There More Caffeine in Cocoa Than Coffee?

There's more caffeine in cocoa than in coffee. Cocoa powder packs 230 mg per 100 grams, surpassing most coffee varieties. Dark chocolate has even more caffeine due to higher cocoa content. It's a rich, unique energy source.

Is There a Lot of Caffeine in Hot Cocoa?

There isn't a lot of caffeine in hot cocoa. It depends on the brand and recipe. Starbucks hot chocolate has around 25 mg per serving, while basic mixes have about 5 mg. The amount of cocoa powder used influences the caffeine content.

Is There Caffeine in Hershey's Cocoa?

Absolutely, Hershey's Cocoa does contain caffeine, but it's not overwhelming. It adds a delightful hint of energy in each spoonful. Perfect for baking or a cozy cup of hot chocolate. Just the right amount!

Is Cocoa a Stimulant Like Caffeine?

Cocoa stimulates like caffeine due to its theobromine content. Decaf versions offer a solution for caffeine-sensitive folks. Options include regular cocoa with caffeine, Dutch-processed cocoa with less, and decaf cocoa with reduced caffeine while keeping healthful compounds.

What are the potential health effects of consuming high levels of caffeine in cocoa?

Unveiling cocoa caffeine levels can lead to potential health effects of excessive consumption. High levels of caffeine in cocoa may contribute to insomnia, nervousness, and fast heartbeat. It can also cause gastrointestinal discomfort and exacerbate anxiety disorders. Moderation in consuming caffeinated cocoa products is recommended for overall health.

Conclusion

To sum up, the caffeine content in cocoa varies depending on the type of chocolate. Dark chocolate typically has the highest caffeine levels, followed by milk chocolate and white chocolate. The amount of cocoa solids in the chocolate also affects the caffeine content.

Remember, just like different chocolates have different levels of caffeine, we all have unique strengths and abilities. Embrace your individuality and always aim for balance in everything you do.

Rachael, the Editor in Chief of RachaelsRawFood.com, is an inspiring and passionate individual who has dedicated her life to promoting the benefits of a raw food lifestyle. Known for her vibrant and energetic personality, Rachael has built a strong online presence that has transformed her personal journey into a thriving community of raw food enthusiasts.

Raw Food Ingredients

5 Key Differences: Caffeine Content in Cocoa Vs Coffee

Open the door to understanding the contrasting caffeine levels in cocoa and coffee, revealing surprising insights that will reshape your beverage choices.

When comparing the caffeine levels in cocoa and coffee, it is important to understand that cocoa generally has lower caffeine content than coffee. Dark chocolate contains approximately 12 milligrams of caffeine per ounce, while hot cocoa typically ranges from 5 to 10 milligrams per ounce. In contrast, brewed coffee can have significantly higher levels, varying from 95 to 165 milligrams per 8-ounce cup.

Cocoa is considered a milder option for individuals aiming to limit their caffeine intake, with theobromine providing a gradual energy increase. Meanwhile, coffee's caffeine content offers immediate alertness, and understanding these distinctions can help you select based on your preferred effects.

Key Takeaways

- Cocoa contains lower caffeine levels but compensates with theobromine for a gradual energy increase.

- Coffee has higher caffeine content, offering an immediate alertness boost and potentially higher metabolic rate.

- Theobromine in cocoa promotes relaxation, while caffeine in coffee provides intense alertness and mood fluctuations.

- Hot chocolate is a good option for reducing caffeine intake while still benefiting from theobromine effects.

- Understanding caffeine variances helps make informed choices for desired energy levels and mood effects.

Caffeine Levels in Cocoa Vs Coffee

When comparing caffeine levels in cocoa versus coffee, it's evident that cocoa generally contains lower amounts per serving. Dark chocolate, made from cacao beans, contains around 12 milligrams of caffeine per ounce, while a 1-ounce serving of hot cocoa mix typically has 5-10 milligrams. Even a 16-ounce serving of Starbucks hot chocolate only contains about 25 milligrams of caffeine.

On the other hand, coffee, when brewed, can range from 95 to 165 milligrams of caffeine per 8-ounce cup, depending on the type and brewing method. This significant difference in caffeine content between cocoa and coffee makes cocoa a milder option for those looking to limit their caffeine intake.

Impact on Alertness and Energy

Typically, the immediate alertness and energy boost from caffeine in coffee can last for hours. This surge in alertness is due to caffeine's stimulating effect on the central nervous system. On the other hand, cocoa contains theobromine, which provides a more gradual increase in energy levels. Unlike caffeine, theobromine doesn't cause sudden spikes and crashes, offering a smoother energy curve.

Coffee's caffeine content can temporarily boost the metabolic rate, potentially supporting weight management efforts. This increased metabolic rate can aid in burning calories and may contribute to weight loss when combined with a balanced diet and regular exercise. Additionally, theobromine in cocoa contributes to the thermogenic effect, leading to mild calorie burning in the body.

Both caffeine and theobromine can influence mood. Caffeine tends to provide a more intense and quick-acting mood elevation, while theobromine promotes feelings of relaxation and contentment. Understanding the differences in alertness, energy, metabolic effects, and mood enhancements between cocoa and coffee can help individuals make informed choices based on their preferences and wellness goals.

Metabolic Variances and Effects

Regarding metabolic variances and effects, the varying caffeine levels between cocoa and coffee play a significant role. When comparing the metabolic impact of caffeine in cocoa and coffee, it is crucial to note that cocoa contains lower levels of caffeine but compensates with theobromine, which aids in the thermogenic effect, promoting calorie burning and metabolic activity. On the other hand, coffee, especially brewed varieties, contains higher levels of caffeine, potentially providing a temporary boost to the metabolic rate, which could assist in weight management. While caffeine in coffee offers a quick energy surge, theobromine in cocoa leads to a more gradual rise in energy levels, avoiding sudden spikes and crashes. To summarize the metabolic differences, I've created a table below:

| Aspect | Cocoa | Coffee |

|---|---|---|

| Caffeine Content | Lower levels | Higher levels |

| Additional Component | Theobromine | Caffeine |

| Metabolic Impact | Thermogenic effect | Temporary metabolic rate boost |

| Energy Levels | Gradual rise | Quick surge |

| Weight Management | Aids in calorie burning | Potential assistance |

Mood Enhancement Disparities

In comparing the mood enhancement effects of theobromine in cocoa and caffeine in coffee, notable disparities emerge in their impact on mental well-being.

The theobromine found in cocoa promotes relaxation and contentment, offering a gradual rise in energy levels that leads to a gentle and long-lasting mood enhancement experience.

On the other hand, caffeine delivers an intense and fast-acting boost in alertness, providing immediate energy levels that can lead to abrupt spikes and crashes.

While both theobromine and caffeine uplift mood, theobromine's effects are characterized by a steady and gradual increase in energy levels, creating a sense of calm and contentment.

In contrast, caffeine's impact is more intense and temporary, resulting in rapid alertness but also the potential for fluctuations in mood. Understanding these differences can help individuals choose between cocoa and coffee based on their desired mood enhancement effects.

Health Implications and Considerations

Health implications and considerations surrounding caffeine consumption warrant close attention due to its potential impact on various aspects of well-being. When comparing a cup of coffee to hot chocolate, it's vital to note the amount of caffeine present.

While coffee contains much caffeine, hot chocolate has less caffeine but isn't entirely devoid of it. The main active ingredients in hot chocolate are theobromine and caffeine, where theobromine is a relative of caffeine and also has stimulant effects, although milder. If you're looking to reduce your caffeine intake, opting for hot chocolate over a cup of coffee can be a good choice.

Being mindful of the caffeine content in chocolate products is important, especially if you're sensitive to caffeine or belong to vulnerable populations like children or pregnant women. Understanding the caffeine levels in different beverages allows you to make informed decisions about your consumption for better overall health.

Frequently Asked Questions

Is There Caffeine in Coffee Vs Cacao Powder?

Yes, there is caffeine in coffee, with around 140 milligrams in a 12-ounce cup. On the other hand, cacao powder contains only about 12 milligrams per tablespoon, making it a great caffeine-free alternative for those seeking a milder boost.

What Is the Difference Between Cocoa and Coffee?

When comparing cocoa and coffee, cocoa offers a rich, chocolatey flavor and is packed with antioxidants and minerals. Coffee, on the other hand, provides a robust, bitter taste and a jolt of caffeine for that morning pick-me-up.

Why Is Cocoa Better Than Coffee?

I believe cocoa is superior to coffee because it offers a gentler energy boost, promotes relaxation and contentment, and provides sustained vitality without sudden crashes. Plus, dark chocolate's theobromine supports cellular health and tastes delicious.

How Much Caffeine Is in Cocoa Powder Vs Decaf Coffee?

In cocoa powder vs decaf coffee, cocoa has 12-26mg of caffeine per tbsp, while decaf coffee holds 2-5mg per 8-ounce cup. The choice hinges on desired caffeine levels and flavor. I prefer cocoa's lower caffeine content.

How does the caffeine content in hot chocolate compare to coffee?

Hot chocolate caffeine content is significantly lower than that of coffee. While an 8-ounce cup of hot chocolate contains about 5-10 milligrams of caffeine, the same size of coffee can have anywhere from 95-200 milligrams. It’s a notable difference for those looking to limit their caffeine intake.

Conclusion

To sum up, while cocoa and coffee both contain caffeine, the levels vary significantly. Cocoa generally has lower caffeine content compared to coffee, impacting alertness, energy levels, and mood enhancement differently.

It's crucial to keep these differences in mind when choosing between the two beverages for your daily consumption. Remember, moderation is key to maintaining a healthy balance in your caffeine intake.

So, whether you prefer a cup of cocoa or a mug of coffee, enjoy it in moderation for the best benefits!

Rachael, the Editor in Chief of RachaelsRawFood.com, is an inspiring and passionate individual who has dedicated her life to promoting the benefits of a raw food lifestyle. Known for her vibrant and energetic personality, Rachael has built a strong online presence that has transformed her personal journey into a thriving community of raw food enthusiasts.

Raw Food Ingredients

A Guide to Becoming a Good King

Kingship demands wisdom, fairness, integrity, courage, and humility – essential traits for a successful reign and prosperous kingdom." Keep reading to uncover the secrets of becoming a good king.

In order to be a good king, one must embody wisdom, fairness, integrity, courage, and humility to lead the kingdom with honor. Wisdom is essential for making important decisions, fairness ensures just treatment for all, integrity builds trust and respect, courage is crucial for facing challenges, and humility reminds us of our humanity. Historical kings such as Solomon, Arthur, David, Charlemagne, and Ramses II serve as role models for these leadership traits.

As a king, embracing challenges, understanding the world, seeking personal growth, and learning from the past are essential responsibilities. Developing leadership skills, making wise decisions, and prioritizing the well-being of the people are key to effective kingship. Every step on the path to becoming a good king is critical for a successful reign and prosperous kingdom.

Key Takeaways

- Embrace wisdom for informed decisions.

- Practice fairness for just treatment.

- Uphold integrity to earn trust.

- Show courage in facing challenges.

- Maintain humility for empathy and respect.

Qualities of a Good King

Being a good king requires embodying qualities such as wisdom, fairness, integrity, courage, humility, and compassion in decision-making and leadership. Power comes with responsibility, and as a king, it's essential to wield this power wisely. Wisdom is vital in making sound judgments that benefit the kingdom as a whole. Fairness guarantees that all subjects are treated justly and equitably, fostering a harmonious society. Integrity is the foundation of trust and respect, key elements in effective leadership.

Courage is necessary to face challenges and make difficult decisions, even when met with opposition. Humility reminds a king of his humanity and the importance of humility in interactions with all subjects. Compassion demonstrates a king's care and empathy towards his people, fostering a sense of unity and loyalty. Effective communication is crucial for conveying decisions, listening to concerns, and inspiring confidence in leadership.

Historical Kings as Role Models

King Solomon, renowned for his wisdom and leadership, stands as an exemplar among historical kings who serve as role models for future leaders. Looking at figures like King Arthur, known for his justice and valor in medieval legends, and King David, celebrated for his faith and courage in battle, we find lessons that transcend time. Charlemagne's legacy of military conquests and cultural revival, alongside Ramses II's grand building projects and military campaigns, offer diverse insights into effective kingship. Below is a table summarizing key attributes of these historical kings:

| King | Attributes |

|---|---|

| King Solomon | Wisdom, leadership |

| King Arthur | Justice, valor |

| King David | Faith, courage |

| Charlemagne | Military prowess, culture revival |

| Ramses II | Building projects, military campaigns |

Studying these historical figures can provide valuable lessons on the multifaceted qualities that make a great ruler.

Responsibilities of Kingship

Embracing challenges and living authentically are central to fulfilling the responsibilities inherent in kingship. As men aspiring to be good kings, it's essential for us to understand that the world requires leaders who are kind, humble, and committed to personal growth.

The journey to becoming a good king involves more than just wielding power and responsibility—it entails sacrificing comfort for growth and transformation. Seeking the ancient path of masculinity, as exemplified by figures like Morgan, teaches us the importance of humility, vulnerability, and character development.

In fulfilling the responsibilities of kingship, we're entrusted with power not for our own gain, but for the betterment of the world around us. Just as seeds need Good Soil to flourish, we must nurture our own growth to lead effectively.

Leadership Skills for Kings

Developing essential leadership skills is crucial for aspiring kings seeking to fulfill their responsibilities with humility, vulnerability, and a focus on character development. As you study the world around us, the power and responsibility of what kingship entails become clearer. Here are some key points to think about on your path to becoming a king:

- Embrace challenges and live authentically.

- Seek ancient paths of masculinity for guidance.

- Reflect on your identity, purpose, and ability to be entrusted with power for good.

- Sacrifice comfort for growth, transformation, and participation in universal creativity.

The journey of becoming a king isn't just about gaining authority but about understanding the remarkable fellowship of like-hearted individuals who share similar goals. Engage in group discussion questions, consider between-session personal study, and explore the depths of your masculine soul. This is the path to restoring what it means to be a true king.

Importance of Wise Decision-Making

Steering through the intricacies of leadership, especially in the domain of kingship, requires a sharp focus on the art of prudent decision-making. Wise decision-making is like the compass guiding the ship of leadership towards success.

Good kings understand that their choices impact not just themselves but also the lives of those they rule over. They prioritize the well-being of their people over personal gains, embodying the essence of true leadership.

Seeking counsel from trusted advisors and reflecting on core values are essential practices in the domain of wise decision-making. By embracing humility and self-awareness, kings can navigate the complex web of choices with clarity and integrity.

Just like a six-session video Bible study can guide individuals in restoring the heart, wise decision-making is essential for becoming the kind of leaders our world needs. Let's start on this journey of radical reconstruction, where every decision is a step towards being counted among the good kings of history.

Frequently Asked Questions

What Is the Becoming a King Guide?

The Becoming a King guide is a transformative resource created by Morgan Snyder to help men grow into responsible kings. It offers practical tools and profound insights to aid personal development and transformation.

What Are the Qualities of a Good King?

Being a good king means embodying humility, wisdom, and integrity. Prioritizing the well-being of my people, making decisions for the greater good, and showing courage, justice, and compassion in all actions. Seeking counsel and valuing diverse perspectives is essential.

What Makes a True King?

Beneath the crown lies a heart that beats with humility and a spirit that soars with honor. True kings are forged in the fires of challenge, embracing authenticity and growth to inspire others.

What Makes a Real King?

Being a true king means embodying humility, courage, and empathy. It's about serving others and leading with integrity. I endeavor to cultivate these qualities daily, embracing challenges and seeking growth in all aspects of my life.

How Can Sacred Cacao be Incorporated Into Kingship Rituals?

In kingship rituals, the sacred cacao ritual holds great significance. The ceremonial drinking of cacao symbolizes the divine connection between the ruler and the spiritual realm. It is believed to impart wisdom and strength, making it a crucial element in the coronation and leadership rites of many cultures.

Conclusion

To sum up, becoming a good king requires a combination of qualities, skills, and responsibilities. Remember, 'With great power comes great responsibility.'

By studying historical kings as role models, practicing leadership skills, and making wise decisions, one can aspire to be a just and effective ruler.

It's a challenging path, but with dedication and perseverance, anyone can endeavor to be a worthy leader for their kingdom.

Rachael, the Editor in Chief of RachaelsRawFood.com, is an inspiring and passionate individual who has dedicated her life to promoting the benefits of a raw food lifestyle. Known for her vibrant and energetic personality, Rachael has built a strong online presence that has transformed her personal journey into a thriving community of raw food enthusiasts.

-

Raw Food Ingredients2 months ago

Raw Food Ingredients2 months agoHow To Make Hot Chocolate With Raw Cacao Powder

-

Raw Food Ingredients2 months ago

Raw Food Ingredients2 months agoHow To Make Chocolate From Raw Cacao

-

What is Raw Food?2 weeks ago

What is Raw Food?2 weeks agoHow To Remove Raw Mustard Oil Smell From Cooked Food

-

Raw Food Ingredients4 weeks ago

Raw Food Ingredients4 weeks agoRaw Cacao Powder How Much For 8 Oz Hot Chocolate Recipe

-

Raw Food Ingredients4 weeks ago

Raw Food Ingredients4 weeks agoThe Truth Behind the Cacao Caffeine Myth

-

Raw Food Ingredients2 months ago

Raw Food Ingredients2 months agoWhen Fasting Can I Drink Coffee With Raw Cacao Powder

-

What is Raw Food?2 weeks ago

What is Raw Food?2 weeks agoHow To Store Raw And Cooked Food Separately

-

Raw Food Ingredients2 months ago

Raw Food Ingredients2 months agoHow To Use Raw Cacao Beans